We Use Polyurethane Injection Foam to Raise Settled Concrete in Greater Portland

Get a faster, affordable alternative to repair your concrete slab

Concrete is a heavy material and so are the vehicles, machinery and structures that concrete slabs and footings are expected to support.

Sometimes, the combined weight of concrete and what it supports causes concrete settlement to occur. The soil beneath the concrete compresses and can cause major problems.

Commercially, concrete roadways can become dangerous or unusable. This often results in sections of runways and parking lots being closed down. In the example of trains, train service can be interrupted because of erosion and settlement beneath the track bed.

This can cause problems at your home as well. Uneven sidewalks, walkways and steps can cause tripping, and sunken driveway slabs can make parking your car in the garage quite a challenge. Polyurethane® is designed specifically to repair this type of problem in Hillsboro, Olympia, Beaverton, Gresham, Corvallis, Tacoma, Bend and the neighboring towns.

Polyurethane geotechnical capabilities:

- Lift settled slabs and slab foundations

- Lift and level sunken sidewalks

- Strengthen and stabilize loose soil

- Fill sinkholes and other voids

- Lift, level and stabilize roadways and airport runways

- Repair and stabilize rail beds weakened by soil washouts

- Treat soil to improve load-bearing characteristics in preconstruction applications

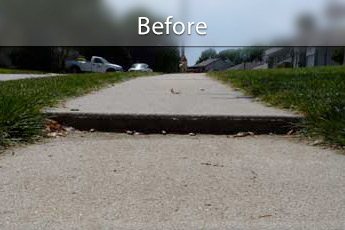

This sidewalk is noticeably uneven, posing a tripping hazard to this high-traffic area.

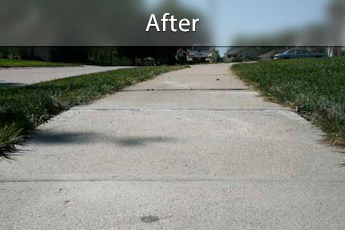

Polyurethane was used to raise the concrete slab & create a safe, even surface.

Polyurethane offers important ADVANTAGES:

- Strong but light. Polyurethane weighs only about 4lbs. per cubic ft., compared to 120lbs. per cubic ft. for standard fill material. Polyurethane ’s light weight makes it useful where denser fill material might impose an undesirable load on weak soils. Despite its light weight, Polyurethane can support substantial loads; it typically provides greater lifting power than mudjacking.

- Waterproof. Once cured, Polyurethane will not wash away. Polyurethane’s waterproofing properties can be beneficial in certain applications.

- Stable and inert. Polyurethane does not react with soil or moisture; it will not leach harmful chemicals into the soil.

- Quick curing. Down time is minimized with Polyurethane® concrete repair. Full loading of the foundation, roadway or other structural element can usually happen about 15 minutes after the material is injected.

- Adjustable. Adjusting the density and expansive force of the 2-part foam affords a wide range of geotechnical uses. Lifting force can be adjusted by fine-tuning the chemical reaction that causes the foam to expand. An experienced applicator can factor not only the weight of the structural element but also soil characteristics and temperature and weather conditions. Special formulations are possible for applications where water must be displaced.

- Noninvasive. Polyurethane injection equipment isn’t bulky, enabling applicators to access confined areas. When properly injected, Polyurethane is not as messy or disruptive as other slab and foundation-lifting techniques.

Polymer injection solves soil settlement and stabilization problems

In the past, contractors often raised settled concrete by pumping a liquid mortar beneath the settled section (called mud jacking). But this pumping process is hard to control, and the added mass of the mortar puts even more weight on the soil.

In the past, contractors often raised settled concrete by pumping a liquid mortar beneath the settled section (called mud jacking). But this pumping process is hard to control, and the added mass of the mortar puts even more weight on the soil.

Fortunately, foundation and concrete repair specialists now have a new technique that’s more effective at raising settled concrete. Polymer injection harnesses the expansive force of a structural grade geopolymer to provide fast concrete leveling, fill voids in soil and strengthen soil that has poor load-bearing qualities.

The polymer consists of two separate liquids that are combined right at the injection nozzle to trigger a chemical reaction that turns the blended ingredients into expanding, high-density foam. The foam flows into voids and between loose soil particles, expanding to about 15 times its initial volume. This expansive action effectively lifts settled concrete. An experienced technician, like those at Concrete Solution Systems, can control the application to create just the right amount of raising pressure.

The polymer begins to harden quickly after doing its raising work. Within just 30 minutes, it reaches 90% of its final strength, enabling damaged concrete roads and slabs to be put back into service right away. The speed of polymer injection repairs is another huge advantage over mortar pumping.

In addition to lifting and realigning settled and/or shifted concrete, polymer injection can be done prior to construction to improve soil stability and strength. Injections as deep as 20ft.-30ft. are possible.

Contact Concrete Solution Systems for expert concrete repair

Ready to see why Polyurethane is the superior choice when it comes to repairing sinking concrete in Greater Portland? Get started by calling Concrete Solution Systems at 1-503-894-0306 or contact us online to meet with one of our specialists today! We provide written estimates for concrete repair in Portland, Vancouver, Salem and throughout the surrounding area.

Learn more…